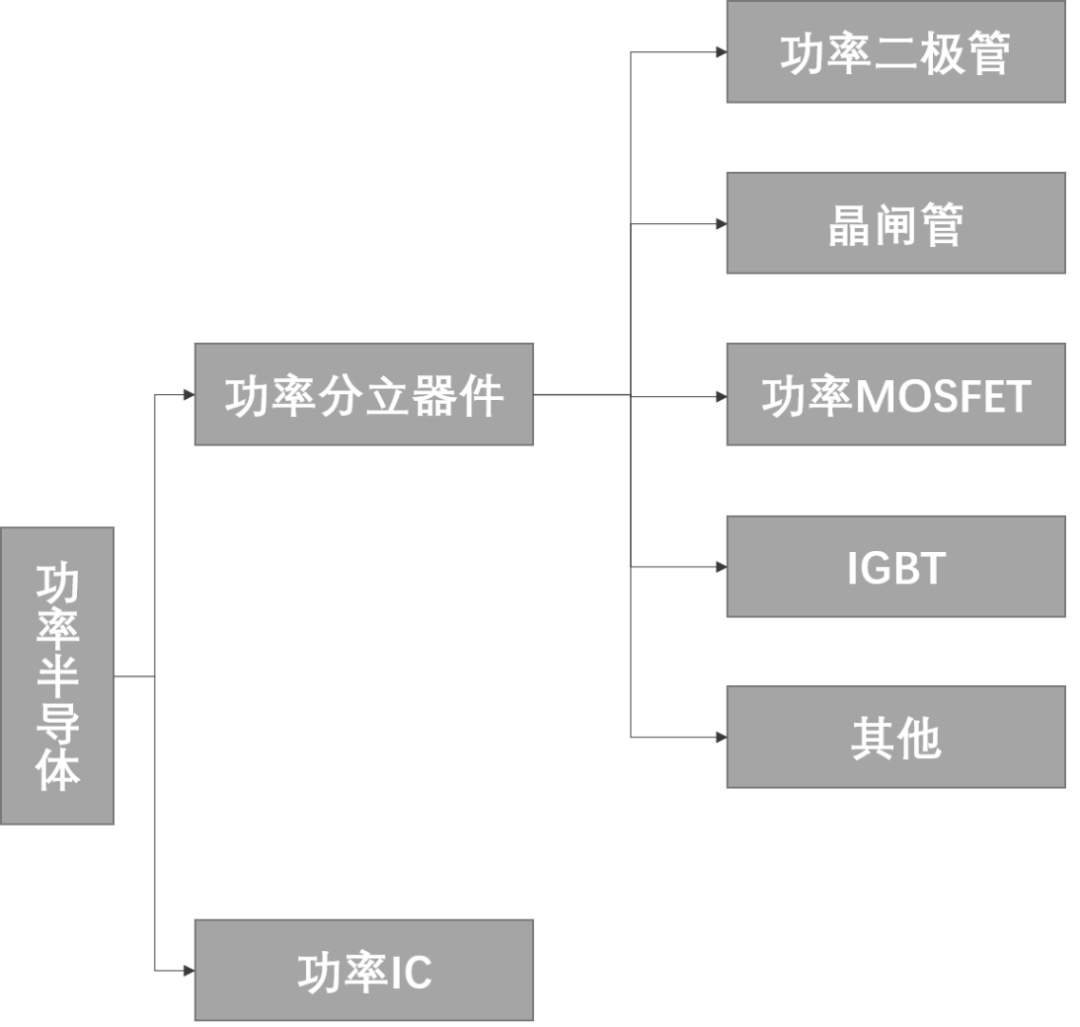

Power semiconductors can be roughly divided into two categories: power semiconductor discrete devices and power semiconductor integrated circuits.

Power semiconductor devices, also known as power electronic devices and power electronic devices, refer to electronic devices that can be directly used in the main

circuit to process electrical energy to realize the conversion or control of electric energy.

Its functions are mainly divided into power conversion, power amplification, power switching, line protection and rectification.

Interpretation one

Classified by semiconductor device structure

According to the device structure, the existing power semiconductor discrete devices can be divided into diodes, power transistors, thyristors, etc., wherein power transistors are divided into bipolar junction transistors (BJT),

Junction field-effect transistors (JFETs), metal-oxide field-effect transistors (MOSFETs) and insulated-gate bipolar transistors (IGBTs), etc.

Interpretation 2

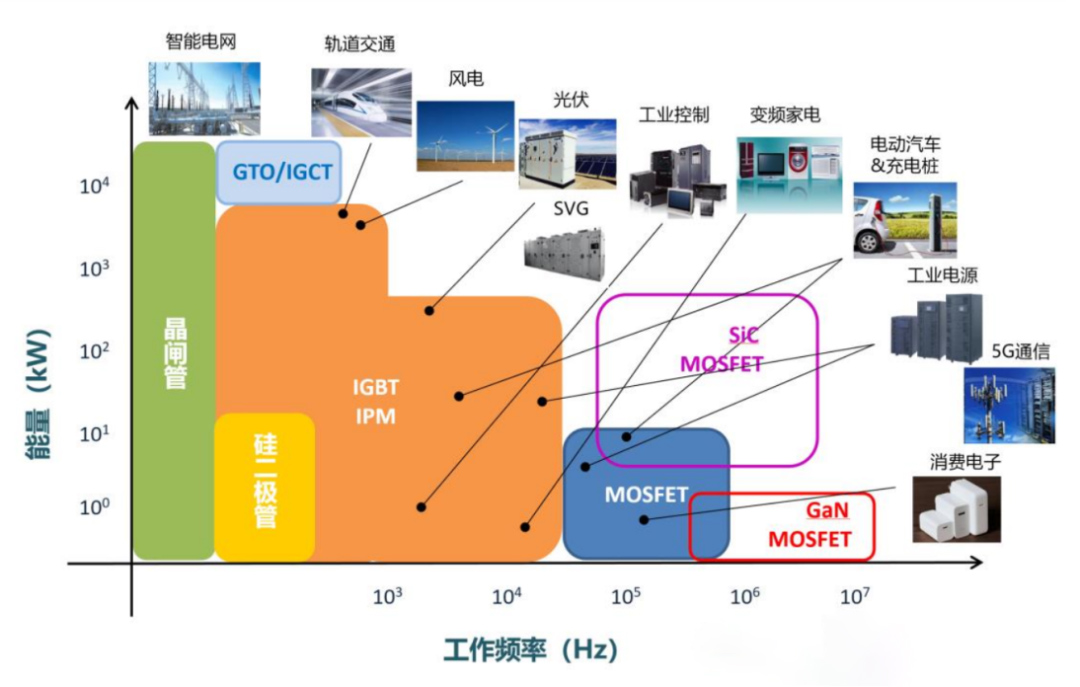

The main application areas of power semiconductor devices

Power semiconductor applications include new energy charging piles, automotive electronics, photovoltaic energy storage, data centers, server and communication power supplies, industrial automation and other fields. In recent years,

new energy vehicles,

Emerging application fields such as charging piles, intelligent equipment manufacturing, and photovoltaic new energy have become the continuous growth points of the power semiconductor industry, and the industry has shown a good

development trend, MOSFET and IGBTEquipower semiconductors have gained unprecedented attention.

Interpretation three

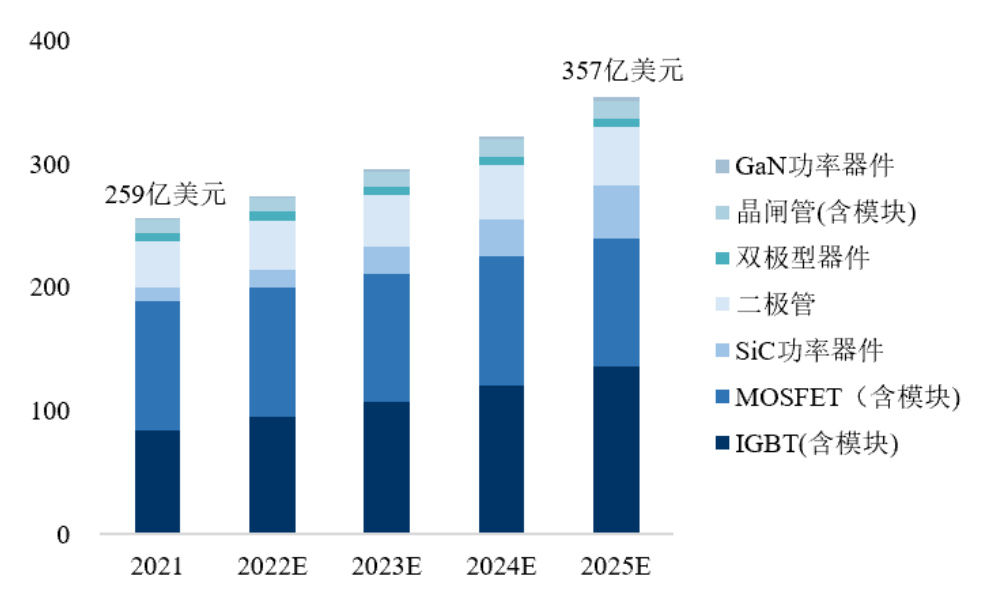

The global semiconductor power device market size and growth rate

From 2021 to 2025, the global semiconductor power device market will increase from US$25.9 billion to US$35.7 billion, with a compound annual growth rate of about 8.4%. The market size of MOSFETs (including modules) in 2021 was

approximately $10.4 billion.

By 2025, it is expected to account for 29%; The market size of IGBT (including modules) will rapidly increase to US$13.6 billion in 2025, accounting for about 38%, with a compound annual growth rate of about 12.8% from 2021 to 2025;

The global SiC power device market size is approximately USD 4.3 billion in 2025, growing at a CAGR of approximately 42% from 2021 to 2025.

Interpretation four

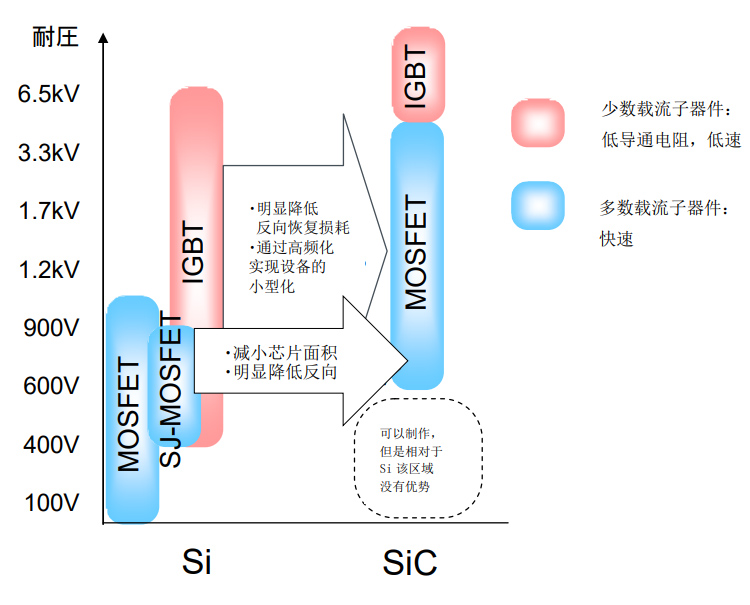

Silicon-based IGBTs and silicon carbide devices

Take, for example, silicon-based IGBTs and silicon carbide devices (SiC MOSFETs, SiC SBDs, SiC modules). IGBT is the most important and widely used product in power semiconductors, which is divided into three categories: single tube, module

and intelligent power module (IPM).

In the field of medium and low voltage, IGBTs are widely used in new energy vehicles and white goods; In the field of high voltage above 1700V, IGBTs are widely used in important fields such as rail transit, clean power generation, and smargrid.

After decades of development, silicon is reaching the limits of its performance, and the potential for improved performance of Si-based devices is getting smaller and smaller. Modern electronic technology has put forward new requirements for

semiconductor materials such as high temperature, high power, high voltage, high frequency and radiation resistance, and wide bandgap semiconductors

For example, SiC is considered to be a material that transcends the limits of Si and is used to make power devices. Silicon carbide devices have the advantages of high power, high voltage resistance, high temperature resistance, high frequency,

low energy consumption, and strong radiation resistance, and can be widely used in new energy vehicles, 5G communications,

Photovoltaic power generation, rail transit, smart grid, aerospace and other modern industrial fields.

Interpretation five

Evolution direction of semiconductor power devices

Although there are differences in the performance requirements of semiconductor power devices in different application fields and application scenarios, they are evolving in the direction of high power density, miniaturization, high efficiency,

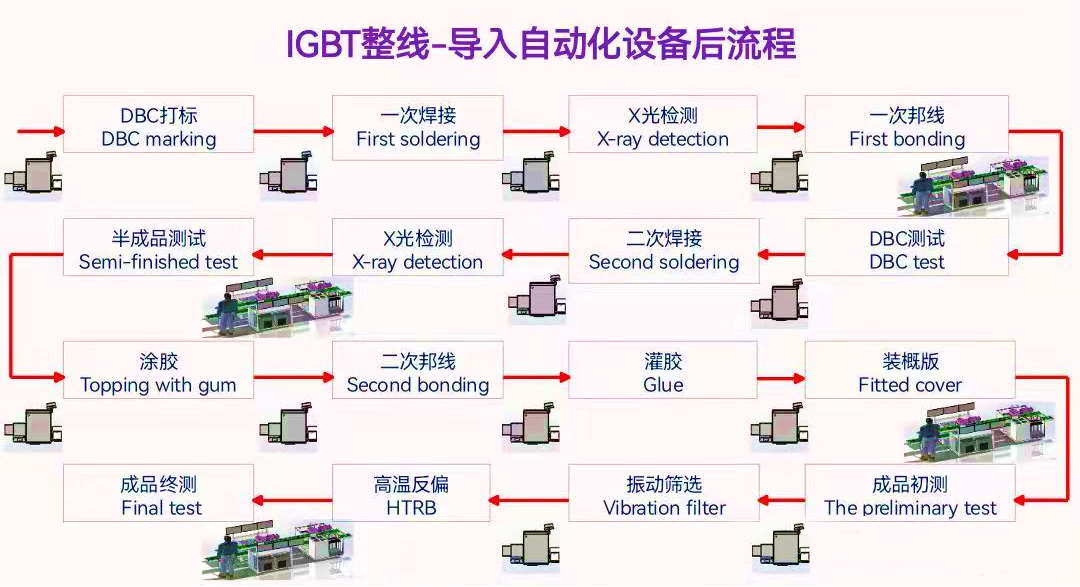

low energy consumption, and high reliability. The core technology of power devices includes the design and production of chips and the design of modules.Manufacturing and testing.

The chip technology has undergone upgrades and iterations, and various indicators such as chip area and switching loss have been continuously optimized. These excellent characteristics need to be perfectly demonstrated by the efficient and

reliable connection of power and signal through packaging and circuit system, and its technical basis mainly includes chip interconnection, chip soldering,The heat dissipation design is then encapsulated through the shell.

The power module is packaged from a variety of materials, including chips, ceramic copper-clad substrates (AMB/DBC), bonding wires (tapes), base plates (made of Cu or AlSiC), heat sinks, potting compounds (liquid epoxy/silicone gel), solder/sintered

silver, plastic housings, etc., and the production equipment involved includes screen printing machinLoading machine, vacuum welding equipment, ultrasonic welding equipment, cleaning equipment, testing equipment, bonding machine, molding equipment, drying equipment, marking equipment, etc.

Related information

-

Wechat

-

Phone

18928454078 -

Tiktok