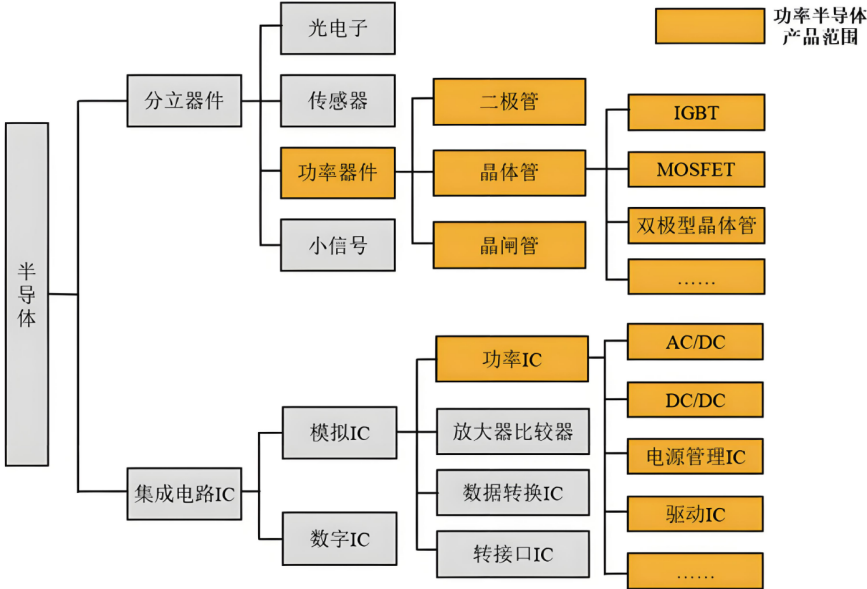

Power semiconductors, also known as power electronic devices or power electronic devices, are one of the core types of devices in the electronics industry chain. It can realize power conversion and circuit control, and mainly plays the role of power conversion, power amplification, power switch, line protection, inverter (DC to AC) and rectification (AC to DC) in the circuit.

Power semiconductors include power semiconductor discrete devices (including modules) and power ICs. Among them, power semiconductor discrete devices, according to the device structure, can be divided into diodes, thyristors and transistors. From the perspective of current market demand, silicon-based MOSFETs, silicon-based IGBTs and silicon carbide are the main products of power semiconductor discrete devices.

1.MOSFET

MOSFETs, which have the advantages of high input impedance, low noise, good thermal stability, simple manufacturing process, and strong radiation, are often used in amplification circuits or switching circuits. MOSFETs can be divided into planar MOSFETs, trench MOSFETs, shielded gate SGT MOSFETs, and superjunction SJMOSFETs according to different processes. According to the conductive channel, it can be divided into N-channel and P-channel, i.e., N-MOSFET and PMOSFET. According to the gate voltage amplitude, it can be divided into depletion type and enhanced type.

As MOSFET technology and processes mature, costs will continue to fall. Mid-to-high-end products will also gradually sink to low-end products. For example, trench MOSFETs will sink from the mid-range to the low-end to replace some of the low-end market of planar MOSFETs. SGT MOSFETs will partially replace the low-voltage market for trench MOSFETs, moving from mid-to-high-end to mid-range.

SGT MOSFET, SJ MOSFET and silicon carbide MOSFET may be the three main products of MOSFET in the future. Since the birth of MOSFETs in the 70s of the last century, from planar MOSFETs to trench MOSFETs, to SGT MOSFETs and SJ MOSFETs, and then to the current hot third generation wide bandgap MOSFETs (silicon carbide, gallium nitride), the technology iteration direction of power MOSFETs mainly revolves around the manufacturing process, design (structural changes), process optimization, and material changes to achieve high performance of devices - high frequency, high power, and low loss.

Automotive MOSFETs: Automotive MOSFETs are widely used in both fuel vehicles and electric vehicles, and MOSFET products are mainly monopolized by overseas companies. Automotive-grade SGT MOSFET MOSFET products with an operating voltage range of 30V-250V, in which medium-voltage (100V-250V) is generally connected in parallel with multiple MOSFET single tubes, which are used in A00-class small electric vehicles or medium-hybrid vehicles (power battery voltage is around 200V) in the main drive inverter, OBC, DC/DC, air conditioning compressor and other components to play the role of inverter and rectification.

High-voltage SJ MOSFETs, automotive-grade SJ MOSFETs typically operate at 650V-900V, and are mainly used in the main drive inverter, OBC, DCDC, and PTC products of 400V power battery platform vehicles that are widely used today.

MOSFET automotive applications (EVs and EVs account for 33% of the total, with EVs and chargers accounting for 25% and 8% respectively.) From the perspective of withstand voltage range, by 2026, low-voltage MOSFETs (0-40V) will account for 39% of the total demand, medium-voltage (41V-400V) will account for 26%, and high-voltage (greater than or equal to 600V) will be widely used in 220V systems, accounting for 35% of the total demand. At the same time, the market penetration of SiC MOSFETs and GaN MOSFETs is gradually increasing.

2.IGBT

IGBT, commonly known as the "CPU" of power electronic devices, is the core device of energy conversion and transmission, which is composed of BJT and MOSFET, and is a fully controlled, voltage-driven power semiconductor device. IGBTs do not have the function of amplifying voltage, and can be regarded as a wire when it is turned on, and as an open circuit when it is disconnected. IGBTs have the advantages of both BJT and MOSFETs, namely high input impedance, low conduction voltage drop, low drive power and saturation voltage drop, etc., IGBTs have the advantage over BJTs or MOS transistors that it provides a larger power gain than standard BJT transistors, as well as higher operating voltage and lower MOS transistor input losses. Therefore, it is widely used in converter systems with DC voltage of 600V and above, such as AC motors, inverters, switching power supplies, lighting circuits and traction drives.

Compared with MOSFETs, IGBTs can continue to operate at higher voltages, while taking into account factors such as high power density, low loss, high reliability, good heat dissipation, and low cost. A high-performance, high-reliability and low-cost IGBT chip not only needs to continuously optimize the device structure at the design end, but also raises higher requirements for wafer manufacturing and packaging.

Automotive IGBTs: IGBTs are typically divided into single tubes, modules, and IPM modules. Global automotive IGBTs, like MOSFETs, are mainly monopolized by manufacturers in the United States, Europe, Japan and other countries. Such as Infineon, onsemi, Fuji Electric, Mitsubishi Electric and SEMIKRON, etc. Among them, Infineon occupies the main market share of automotive IGBTs, and Infineon first launched the HybridPACK series of automotive-grade IGBT modules in 2007. In the domestic market, BYD, Star Semiconductors and Times Electric ranked in the top ten.

IGBTs have been developed into the seventh generation, and Infineon, as the leading IGBT leader, has been iterating to the seventh generation of its technology as early as 2018. The fifth, sixth, and seventh generations are all designed and optimized for high-power, high-switching frequency, etc., based on the fourth-generation technology. Different generations correspond to different device designs, as well as different device performance and application scenarios. At present, most domestic manufacturers have developed to the same as Infineon's fourth- and fifth-generation technologies, and the fourth- and fifth-generation IGBTs are also the mainstream technologies for the current automotive IGBT applications.

The application prospects of power semiconductors are broad, covering almost all electronic industry chains. Power devices such as MOSFETs, IGBTs, and SiC MOSFETs are in high demand. According to different performance, it is widely used in many fields such as automobiles, charging piles, photovoltaic power generation, wind power generation, consumer electronics, rail transit, industrial motors, energy storage, aerospace and military industry.

Taking MOSFETs as an example, Yole predicts that the total global MOSFET market (including discretes and modules) is expected to reach $9.48 billion by 2026, growing at a CAGR of 3.8% (2020-2026). According to the China Business Industry Research Institute, transistors represented by MOSFETs and IGBTs account for the largest proportion of power semiconductor discrete devices, about 28.8%.

Related information

-

Wechat

-

Phone

18928454078 -

Tiktok